It was a very busy week last week. Of course, a large cabinet order for a kitchen had to be edited while I was away, which I did (while I was away). Then, it had to be looked at in its entirety again right after I got back, to do the back and forth editing with the factory, which I did, and have just finished.

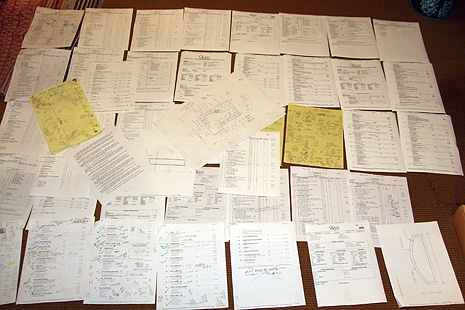

I thought it would be interesting to give you a little glimpse of what is involved in ordering a kitchen, this stage of the order processing, which is the final stage. It's a stressful time. It's decision time, fish or cut bait, do or die, last chance and all that!

I do things the long way. When I put in my cabinet order, it's probably 95% accurate. Usually, that is because I need to rush the order writing somewhat so that I can reserve a particular week for delivery...timing is always critical in my line of business! At this time, the client and I go over the final plans and they place the deposit with me. In the course of going over every final detail, more issues often arise, changes, rethinking, etc. on the part of the client. I permit that, I never discourage it, because I want my clients to have things "their way." I want them to have every opportunity, even if it comes later than it should, to make their kitchen the way they want it.

Sometimes, as in this case, the client kept thinking and rethinking things well after we first placed the order, and I continued to accommodate this client until the day before I left for my trip (a surprise two hour meeting!) And, then we emailed and spoke again while I was away!

When the factory gives me back their interpretation of my written order, and before production, it looks like the image, here! I need to start from scratch with every single dimension for the entire room, taking another look at a couple of hundred+ cabinet order details, and taking everything else (appliance specs & more) into consideration all over again. That's how I do it. It takes focused concentration for long periods of time. As a result, I never, ever, have a problem with a cabinet's fit, and I'll often come up with new, better, ways of detailing a cabinet during this time.

There are four pieces of information that I check, one against the other, constantly: the specifications list in the contract, the floor plan and elevations, my order to the factory, and the original dimensions from the space. Back and forth, one to the other and back again.

Sometimes I have not been 100% clear in the order, and sometimes the factory makes a mistake or misinterpretation on their edited copy of the actual order. They check me, and I then check their final interpretation before it goes into production. We communicate via phone and email. To me, it's not over until it's the last day before production (well, the goal is to have it be over when the factory begins their editing process!) You can get a sense of how detailed a designer is if you ask him/her to tell you how he/she edits their orders with the factory. Sometimes I call it engineering the cabinetry to fit, as I design all cabinetry to the 1/8". If they roll their eyes at the thought of this stage of the process, it's a good sign! Now the order is done, and guess what, when the cabinets arrive, I'm doing the whole thing all over again to remember why I did what I did!